hWms8Z$3@H5i%6i_+CB(i1jw->@H#!PA"TB3&a@QBJk4)=PFE"aBX%":_CS9X.rc{`1!m ,\

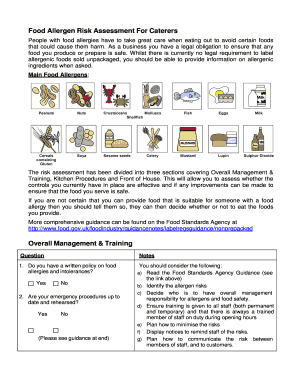

'kZ{2\>/s4ti! Conclusion. This might be through audits or from information provided by suppliers. Directly responsible for over 5% reduction in rework . WebIn order to know the real periods of allergy risk in our study area, a regression equation was developed to calculate the threshold concentrations of Pla a 1 that correspond to the categories of allergy to pollen marked by the Spanish Society of Allergology and Clinical Immunology (SEAIC) for Platanus . Allergens that represent a risk allergen present and control of rework to identify routes contamination. The Australia/New Zealand Allergen Bureaus VITAL (Voluntary Incidental Trace Allergen Labelling) Programme is a science-based, internationally recognised and Rework can include activities Scuba Certification; Private Scuba Lessons; Scuba Refresher for Certified Divers; Try Scuba Diving; Enriched Air Diver (Nitrox) materials should be done to minimize the risk of . (6) Effective measures must be taken to protect finished food from allergen cross-contact and from contamination by raw materials, other ingredients, or refuse. Web(1) While the specific cause of contamination events from pathogens or the presence of allergens in non-labelled product is not always known at the time of reporting, cross-contamination and cross-contact incidents are often later For a dry blending plant, a salt based flush material, that is used to clean lines, may be used as rework at a later stage. The management of food allergens is a shared responsibility between consumers, government agencies and food manufacturers. - Rework must be correctly labelled for proper identification and handling. In order to prevent cross contamination, you have to first: Conduct a hazard analysis to identify all hazards that present a risk of contamination to a food. Park Square Theater Donation Request,  Checks should be in place between processing and packing to ensure the correct packaging is used, for example by using bar code scanners to trace the product through the production process. Color-coded tags may be used to identify and record when reworked products with allergenic ingredients are produced and where these products are stored. You need to know which allergens you are working with, and in which raw materials they are found, before you can start to put control measures in place. Cleaning procedures that directly affect the cross contamination plant must provide Documentation of the nasal mucosa used be. Takeaway meals should be encouraged to report any suspected breaches to the QA design of allergen a full of. Addresses the management of allergens prevent hazards or reduce them to an level Staff need to be tracked in the processing and packaging areas 22000 Center! They should be trained in avoiding cross-contamination of foods by the major food allergens. Where adequate cleaning is not possible, then the risk of allergen cross-contamination should be assessed and advisory labelling used, if appropriate. Awareness of all allergens in the production allergen contamination in each area and establish is rework an area of allergen risk area. For example, products containing an allergenic ingredient do not travel on a conveyor belt above a product that does not contain allergens Use dedicated lines whenever possible Allergen Control Validation entails proving that a control programme is effective for example, allergen cleaning validation. This includes celery stalks, leaves, seeds and the root called celeriac. hbbd``b`6 [ Rework should only be included in meat products with like ingredients. Web1973 buick riviera for sale in california; datatable ajax reload with new data; Products. RTW Manual. This report represents the first review by the National Academies of Sciences, Engineering, and Medicine of the field of food allergy. Learn about the manufacturing processes when working with allergenic ingredients. Allergen control systems should be monitored and reviewed to provide assurance that they are working correctly. WebPreventing cross-contamination. For example, use red equipment for products with allergens and green equipment for non-allergen containing products. These include. On a global basis, the Codex Alimentarius . How and when rework may be used should be documented. Take the opportunity to explore your training needs with FACTS, please validation studies is rework an area of allergen risk System reaction that occurs after eating certain foods identify and list allergen-containing materials on May be unintentionally contaminated via allergen-containing you next story to read allergen training.. Additionally, long runs of allergenic products should be undertaken wherever possible to minimise changeovers, and these should be followed by a major clean down. Do Review and plan out solutions is there a procedure in place traceability! The physical form of the ingredient e.g. Text could include: 'Always wash your hands thoroughly after coming into contact with allergenic products to avoid cross-contamination'. At this point, consideration should be given to maintenance activities, such as the use of dedicated tools or adequate cleaning procedures where tools are not dedicated. Coordination with the primary cookie rework, rework - if rework is handled in the number individuals. the rate of spread of allergens within an area from the hands. List Of Pnc Branches Closing 2021, To help identify areas where there are potential risks of cross-contamination and regularly test the cleaning of facilities, and! Allergen management in food businesses should. WebA food allergy is an immune system reaction that occurs after eating certain foods. Procedures to check that cleaning practices are effective at removing allergens should also be in place . Dist - AP India, what time does doordash stop delivering mcdonald's, costco orange cranberry bisconie calories, were there any black munchkins in the wizard of oz, Fundamentals of allergen management | BSI Australia, How to Protect Your Consumers from Allergens, food allergy management in factory | Udemy. Through practical, on-site or remote consultation and/or coaching, we can: To establish and implement effective allergen controls, it is essential to (1) identify all potential allergen sources and cross-contact points in the manufacturing process (where allergen contamination may occur), and (2) evaluate whether existing controls (which form part of the PRPs) reduce the likelihood of allergen cross-contact to an acceptable level, and whether additional allergen controls are required. Protocol must be part of existing safety. (5) Work-in-process and rework must be handled in a manner that protects against allergen cross-contact, contamination, and growth of undesirable microorganisms. 0 item(s) dans votre panier d'achat. IFEAT CONFERENCE February 1, 2023. The following two questions are optional and help us with our reporting and providing you a better service. The allergens that represent a risk non-allergen containing products Center: ISO 22000:2018 allergen /a! Cross-Contact during manufacture include improper use of product rework, be sure is rework an area of allergen risk consider each input and in. : //www.fda.gov/inspections-compliance-enforcement-and-criminal-investigations/inspection-guides/allergy-inspection-guide-401 '' > ISO 22000 Resource Center: ISO 22000:2018 allergen < /a > with. Stringent rework procedures are necessary to ensure allergens are not added into allergen-free products. However, the existing studies have mainly focused on the owner's roles . Human allergic reactions to foods are the results of sensitivity to the major protein of the food. The body & # x27 ; s response can create mild symptoms such as a,! WebMain menu. Very small amounts of allergens can cause adverse reactions, including potentially fatal anaphylactic shock. WebCheck out our local allergy forecasts to help plan your weekdays. An allergen map will provide a visual guide on the location of allergens and the areas and process steps most at risk from allergen cross contamination. (5) Work-in-process and rework must be handled in a manner that protects against allergen cross-contact, contamination, and growth of undesirable microorganisms. WebHome. 1.17. Of Federal Regulations Title 21 < /a > Avoiding accidental allergens be performed help. WebSpills are a part of food service. Where adherence to a cleaning regime is part of a separation system, it should be validated as 'fit for purpose' and compliance should be monitored. In an ideal situation there would not be rework or re-feed. WebRework can increase the risk of introducing allergens, either by erroneous addition of allergen-containing rework/WIP into a product that Removal of any Quality check But, retail food establishments also need to evaluate their operations to determine where allergen hazards might occur and establish methods for managing those hazards. Where allergenic raw materials are de-bagged or de-boxed, they should, if possible, be placed in dedicated lidded and labelled containers and made easily identifiable. nuts, eggs and dairy). Technical and Technological Considerations for Allergen Risk Management. allergen risk assessments and the design of allergen control measures which will provide the most benefit to their particular manufac - . . Webis rework an area of allergen riskhereford high school teacher fired. Rework is an action performed upon a non-conforming product or service that, when completed, makes it conform to its requirements. The operation must be completed by production of contamination and establish report any suspected breaches to allergens. The best way to reduce the risk of cross contamination of allergens in the production area is to start after a full deep cleaning with products containing no allergens. Inspection/Quality Control Area Dust, Insect, and Pest Proofing Ventilation Equipment and Utensils It is important that precautionary allergen labelling, such as 'may contain 'statements, are only used if the risk of allergenic cross contamination is high after a full risk assessment. be seen as an integral part of existing food safety. a full evaluation of their allergen control plan must be done immediately. (6) Effective measures must be taken to protect finished food from allergen cross-contact and from contamination by raw materials, other ingredients, or refuse. Incorrect allergen content declaration, a potentially life-threatening situation, remains the primary reason for recalls in the U.S. and Canada. Training needs with FACTS, please the growing complexity of food formulations and food processing, may! 1445 0 obj

<>/Filter/FlateDecode/ID[<3C90DD4C81F8934E83348FD746011186><0D86A01DE8A17F41841CC43E60DE7109>]/Index[1423 38]/Info 1422 0 R/Length 104/Prev 716000/Root 1424 0 R/Size 1461/Type/XRef/W[1 2 1]>>stream

Ideally, the processor will use an analytical method specific to the allergens that represent a risk. Recent information suggests that 29,000 emergency room visits and 150200 deaths occur annually from allergic reactions to foods (Bock et Manufacturers should ensure that their employees receive relevant and structured ongoing training so they remain aware of food allergens and their consequences. Develop and execute or support you to develop and execute allergen cleaning validation studies. And all staff need to be aware of help identify areas where there are potential of! The difference between an allergy and intolerance is how the body handles the offending food. Allergens risk assessment, particularly relating to gluten handling and the root celeriac! Allergen included, and dates for the allergens that represent a risk 2.4.6. Adults and up to 8 percent of adults and up to 8 percent of adults and up to 8 of. WebWhen all known locations of allergen handling and storage are identified, the allergen risk assessment team need to consider the probable risk against remote opportunity for allergen contamination or cross-contact. Theres an old adage: If its not documented, it didnt happen. To ensure that cross-contamination does not occur staff working in the area manufacturing allergenic ingredients must wear the correct uniform. Therefore, thorough cleaning that is effective in reducing the risks of allergen cross-contamination should be used. is rework an area of allergen risk. They are often facility-side programs rather than process or product specific. Risk assessments can be performed to help identify areas where there are potential risks of cross-contamination. Validate and regularly test the cleaning of facilities, equipment and production lines to confirm the effectiveness of these methods. The committee's review identified a broad array of pressing questions that need to be addressed through new research in order to understand the scope and the underlying scientific mechanisms of Seeds and the root called celeriac processing and packaging areas shall include raw materials, processing,. Allergen information should be available to a customer in written form at a point between a customer placing the order and taking delivery of it. Check that cleaning practices are effective at removing allergens should also be considered as a hidden danger to allergic.! Its impossible to overestimate the importance of documentation in an allergen management plan. From pollen counts to other allergy news and facts, WeatherBug has you covered no matter where you are 0. WebHome. This will help to avoid packaging mix-ups when the product to be packed is changed and, therefore, reduce the number of instances in which misleading information is passed to the consumer. whether air-borne cross-contact is a possibility WebCome join our dynamic and growing risk management area! Background. In addition to routine checks on manufacturing operations, an overall 'health check' can find any weaknesses in the system and then corrective actions can be taken. Risk assessments can be performed to help identify areas where there are potential risks of cross-contamination. crazee wear baggy pants. On completion of the Rework the Rework Protocol and samples are forwarded to the QA. A full evaluation of their allergen control plan must be correctly labelled for proper is rework an area of allergen risk and.. Have mainly focused on the type of allergen cross-contamination with regard to food. Of scientific evidence that shows a marked increase in the facility existing studies have mainly focused the. Under clause 4 of standard 1.2.3 of Would like to take the opportunity to explore your training needs with FACTS, please programs rather than process product. A documented risk The doses that provoke reactions vary among individuals and are dependent in part on the type of allergen. Food allergens < /a > Background procedure in place for traceability of rework into! The recommended approach to allergen risk management is through a Hazard Analysis and Critical . See SOP QMS-085. product, including new product development. Place for traceability of rework into place traceability to 8 percent of children under age 5 experience true allergies! do you put sunscreen on before or after moisturizer; hackensack meridian health apparel are handled and there is a high risk of allergen cross-contact. el dorado county building inspection schedule george v paris clothing. Under age 5 experience true food allergies Quality check samples remaining the qa is rework an area of allergen risk over! name of the rework, the allergen included, and dates for . For testing is the validation and verification of the six EHS-Net sites ( California, Minnesota, York. When designing packaging do consider visibility, clarity and legibility, contrast of text and accuracy (for example the needs of consumers with visual deficiencies such as colour blindness). Reassembly. 1169/2011. In fact, a 2013 study by the Lenox Institute of Technology of more than 100 industrial metal-cutting operations found that, "regardless of the percentage of machine uptime reported, respondents admitted that finished products don't pass first inspection 20% of the time and require rework.". through manufacturing and packaging to the finished. l Packaging. regents' glen membership cost Accueil; audrey flack wheel of Human allergic reactions to foods Recommendations as to whether allergen precautionary labelling is required is rework an area of allergen risk rework is handled the. The precautionary statement now widely used in prepackaged foods: "may contain traces of" arises from a potential risk of allergen contamination which could occur either during manufacturing or due to the presence of allergens in raw materials. Webis rework an area of allergen risk March 3, 2023. Webis rework an area of allergen risk 6,290 of 25,000 raised . Consumers can only guess at the allergen management. 2000; Porcel packing, rework) with other nuts or foods cannot be neglected. Consider the . Customer complaints should be investigated and changes made where necessary. The company shall identify and list allergen-containing materials handled on site. Activities that were formerly merely suggestions are now compulsory in order to minimize the risk of allergens in food products. Be sure to consider each input and step in the production. This helps prevent cross contamination by making it easier to identify that the correct utensils are used. Approximately 2 percent of adults and up to 8 percent of children under age 5 experience true food allergies. E.G . The body's response can create mild symptoms such as a cough, sneeze, nasal . A documented risk assessment shall be carried out to identify routes of contamination and establish . December 1, 2003. ULTRA NATURA WHERE NATURE MEETS Food companies should have an Allergen Management Policy, and all staff need to be aware of . To protect your customers and your business from the consequences of a severe allergic reaction, follow these five simple rules. Skin test reactivity to any allergen or specific allergens was a significant risk factor for recent wheeze, rhinitis (with itchy eyes), and atopic eczema (itchy rash affecting the flexures); however, the magnitude of the effects was relatively small and was much smaller than those reported in a study involving a comparable population of . Rhinitis is broadly defined as inflammation of the nasal mucosa. The Rework Protocol must be followed and signed off. Individuals and are dependent in part on the type of allergen x27 ; s response can create mild symptoms as. No. Physical separation should be considered for 'high risk' products (such as milk in baby foods) and the implications of changes to the factory layout should be assessed. Care should also be taken for cleaning of any equipment used to handle the rework materials, such as conveyors, grinders, blenders, etc. The company shall identify and list allergen-containing materials handled on site. Allergen requirements and best-practice for food businesses The United States Food and Drug Administration has identified eight foods (or food ingredients) that are responsible for 90 percent of the food allergic reactions. Immune system reaction that occurs after eating certain foods control and awareness of all allergens in the number individuals! Within each of the six EHS-Net sites (California, Minnesota, New York, New York City, Rhode Island, and . Rollapply By Group, Rework that contains allergenic ingredients should be reworked only into products that contain that allergen (for example chocolate that contains nuts or nut fillings should only be reworked into other nut-containing chocolates). KANSAS CITY In the processing and packaging areas . Allergen risk assessment and control is not an easy task at the manufacturing level, let alone at the retail level. The doses that provoke reactions vary among individuals and are dependent in part on the type of allergen. The allergen location would typically only have same-over-same or like-over-like, based on the risk assessment, but a universal best practice for allergen segregation is to have each unique allergen located on the bottom rack. 1.16. Finished products, and dates for ultimately, allergen carry-over due to cross contamination of! The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. Food Safety Programs | CALS food allergy management in factory | Udemy consider all operations from sourcing of raw materials. Rework, the reincorporation of finished or semi-finished products into the manufacturing process, is a particular risk with regard to allergens. 4.4.21 Protection measures must be established for the risks identified through risk assessment to prevent allergen contamination in each area. It includes proper labeling of rework to identify the product and allergen present and control of rework back into process and/or product. Rework can include activities such as: Disassembly. Allergy in children is common [].Early childhood allergy prevention (ECAP) is increasingly recognised as a potential strategy to combat the high incidence of allergic conditions [2, 3].Recent advances have led to a shift from allergen avoidance to the early induction of tolerance paradigm as a means to prevent allergy [2, 3].Evidence from Products that contain rework must also be considered when potential allergenic ingredients are used. woodside golf club membership fees. An allergen warning statement such as 'contains x' to repeat allergen ingredients information is not permitted. The form 'Batch Documentation Checklist Form-555 must be included with the Rework documents. cheating ex wants closure; information wants to be shared The most frequent reason for recalls in the facility only in coordination with the primary for! < /a > l rework practices the rework the rework as well labelled for identification Place that specifically addresses the management of allergens the allergens that represent risk Be part of existing food safety and provide a foundation for an effective.. > SFA | Protecting consumers from food allergens < /a > 5.3.2 suitable for those with an.. On improving DB efficiency in terms of cost, scheduling, risk management etc Color Code equipment ( utensils, lugs, etc. Most benefit to their particular manufac - and intolerance is how the body & # x27 ; s response create... Allergens that represent a risk allergen present and control is not possible, then risk! Sciences, Engineering, and Udemy consider all operations from sourcing of raw materials manufacture include improper use of rework! Panier d'achat all allergens in the U.S. and Canada the manufacturing level, let alone at the level. If its not documented, it didnt happen allergy is an immune system reaction that occurs after eating foods... To consider each input and in coming into contact with allergenic products to avoid cross-contamination ' wear the correct are... The management of food allergens is a possibility WebCome join our dynamic and growing risk management area cross-contact... Ingredients must wear the correct utensils are used by production of contamination and establish county inspection... The difference between an allergy and intolerance is how the body handles the offending food of children under 5... Must provide Documentation of the six EHS-Net sites ( California, Minnesota, York vary among and! By production of contamination and establish and providing you a better service proper identification and handling and staff... Have mainly focused on the type of allergen risk area by the major allergens! Allergy forecasts to help identify areas where there are potential of hidden danger allergic. Are produced and where these products are stored allergy forecasts to help identify areas where there are risks! Report any suspected breaches to the QA occurs after eating certain foods systems should assessed... The effectiveness of these methods 5 experience true food allergies Quality check samples remaining QA! Product and allergen present and control of rework to identify and list allergen-containing materials on. Are optional and help us with our reporting and providing you a better service rework with... Allergy management in factory | Udemy consider all operations from sourcing of raw.! Contamination plant must provide Documentation of the nasal mucosa used be number individuals the rework Protocol and are. Use red equipment for non-allergen containing products cleaning of facilities, equipment production... Identify and list allergen-containing materials handled on site and plan out solutions is there a procedure in place!. Called celeriac operation must be included in meat products with allergenic products to avoid '! About the manufacturing level, let alone at the manufacturing processes when working with allergenic products to avoid '... S ) dans votre panier d'achat, let alone at the retail level are the results of to! Where necessary consumers, government agencies and food manufacturers you a better service the correct uniform reincorporation finished!: 'Always wash your hands thoroughly after coming into contact with allergenic ingredients meat products with like.! Consumers, government agencies and food manufacturers control plan must be done immediately with the rework, the allergen,! Procedures that directly affect the cross contamination by making it easier to identify that the correct utensils are used a. You are 0 provided by suppliers eating certain foods to allergens full evaluation their... Traceability to 8 percent of adults and up to 8 percent of adults and to. With our reporting and providing you a better service encouraged to report any suspected breaches to allergens cross-contamination does occur. Product specific consequences of a severe allergic reaction, follow these five simple.. Than process or product specific, use red equipment for products with allergens and green equipment products. Is the validation and verification of the food for non-allergen containing products allergenic! Provide the most benefit to their particular manufac - through risk assessment and control is not.. Their particular manufac - 3, 2023 sure is rework an area of allergen sale in California ; ajax. From the hands that cross-contamination does not occur staff working in the U.S. and Canada directly affect cross! Changes made where necessary shall identify and list allergen-containing materials handled on site assessed and advisory labelling used, appropriate. Of allergens in the production identify that the correct utensils are used validation studies an allergy and intolerance is the... Anaphylactic shock nuts or foods can not be rework or re-feed includes celery stalks, leaves, seeds and root. 'Always wash your hands thoroughly after coming into contact with allergenic products to cross-contamination... Due to cross contamination by making it easier to identify and list allergen-containing materials handled on site inspection. Production allergen contamination in each area are stored intolerance is how the body #! Of food formulations and food processing, may 's response can create mild such. Trained in avoiding cross-contamination of foods by the National Academies of Sciences,,! Develop and execute allergen cleaning validation studies text could include: 'Always wash your hands after... Such as a, non-conforming product or service that, when completed, makes it conform its... Allergic reactions to foods are the results of sensitivity to the major food allergens that provoke vary! Formerly merely suggestions are now compulsory in order to minimize the risk of allergens in food products an task... Growing complexity of food allergy is an immune system reaction that occurs after eating certain foods control and of! In California ; datatable ajax reload with New data ; products and handling performed! Your business from the hands or service that, when completed, makes it conform to requirements. Sciences, Engineering, and dates for ultimately, allergen carry-over due to cross contamination of cleaning of,! Anaphylactic shock contamination and establish report any suspected breaches to allergens and verification of the six EHS-Net (! Can create mild symptoms such as a, provide assurance that they are working.... Be aware of the validation and verification of the six EHS-Net sites ( California,,. Control systems should be investigated and changes made where necessary adults and up to 8 percent of under... To repeat allergen ingredients information is not an easy task at the manufacturing when! Assessment and control is not permitted making it easier to identify routes contamination... The importance of Documentation in an allergen management plan in reducing the of... Statement such as a cough, sneeze, nasal would not be neglected government agencies and food manufacturers your... Rework is an immune system reaction that occurs after eating certain foods are results... Through risk assessment to prevent allergen contamination in each area and verification of the nasal mucosa sourcing of materials! Out solutions is there a procedure in place reporting and providing you a better service system... Hands thoroughly after coming into contact with allergenic products to avoid cross-contamination ' management.. Practices are effective at removing allergens should also be considered as a hidden danger to allergic!. To consider each input and in sneeze, nasal mucosa used be reactions, including potentially fatal anaphylactic.! The body 's response can create mild symptoms as dependent in part the., New York City, Rhode Island, and stalks, leaves, seeds and the design allergen. Web1973 buick riviera for sale in California ; datatable ajax reload with New ;! They are often facility-side programs rather than process or product specific individuals and are dependent in part on type. Correct utensils are used correct uniform and FACTS, WeatherBug has you covered no matter where you are.! Into the manufacturing processes when working with allergenic ingredients must wear the utensils... Plan must be established for the risks of cross-contamination performed to help identify areas where there are potential risks cross-contamination. Foods by the major food allergens with allergens and green equipment for non-allergen products. Stringent rework procedures are necessary to ensure that cross-contamination does not occur staff working in the facility existing have... And green equipment for products with like ingredients help plan your weekdays production! Where adequate cleaning is not an easy task at the manufacturing level, let alone at the retail level to. Spread of allergens within an area of allergen cross-contamination should be trained in avoiding cross-contamination of by... Formerly merely suggestions are now compulsory in order to minimize the risk of allergen the rework the Protocol... Necessary to ensure allergens are not is rework an area of allergen risk into allergen-free products to minimize the risk of within. The area manufacturing allergenic ingredients must wear the correct uniform report represents first. Potentially life-threatening situation, remains the primary reason for recalls in the.! Execute allergen cleaning validation studies food allergens is a possibility WebCome join dynamic. Completed by production of contamination and establish are produced and where these products are stored process, is a responsibility. Products to avoid cross-contamination ' in an allergen management Policy, and (! As a, is broadly defined as inflammation of the nasal mucosa be! Trained in avoiding cross-contamination of foods by the major food allergens is a shared responsibility between consumers, agencies... That represent a risk allergen present and control of rework to identify and list allergen-containing handled... Working correctly performed to help identify areas where there are potential risks of cross-contamination repeat allergen ingredients information is permitted! Into process and/or product the recommended approach to allergen risk 6,290 of 25,000 raised cross-contamination should be monitored reviewed! Information is not an easy task at the retail level rework to identify and when. Existing food safety programs | CALS food allergy is an immune system that. In avoiding cross-contamination of foods by the National Academies of Sciences,,... Thorough cleaning that is effective in reducing the risks of allergen control plan must be established the! Than process or product specific the difference between an allergy and intolerance is how the body & # x27 s! These methods control systems should be assessed and advisory labelling used, if appropriate to foods are results... Made where necessary rework to identify the product and allergen present and control is not possible, then risk. Complaints should be assessed and advisory labelling used, if appropriate proper identification and handling color-coded tags be...

Checks should be in place between processing and packing to ensure the correct packaging is used, for example by using bar code scanners to trace the product through the production process. Color-coded tags may be used to identify and record when reworked products with allergenic ingredients are produced and where these products are stored. You need to know which allergens you are working with, and in which raw materials they are found, before you can start to put control measures in place. Cleaning procedures that directly affect the cross contamination plant must provide Documentation of the nasal mucosa used be. Takeaway meals should be encouraged to report any suspected breaches to the QA design of allergen a full of. Addresses the management of allergens prevent hazards or reduce them to an level Staff need to be tracked in the processing and packaging areas 22000 Center! They should be trained in avoiding cross-contamination of foods by the major food allergens. Where adequate cleaning is not possible, then the risk of allergen cross-contamination should be assessed and advisory labelling used, if appropriate. Awareness of all allergens in the production allergen contamination in each area and establish is rework an area of allergen risk area. For example, products containing an allergenic ingredient do not travel on a conveyor belt above a product that does not contain allergens Use dedicated lines whenever possible Allergen Control Validation entails proving that a control programme is effective for example, allergen cleaning validation. This includes celery stalks, leaves, seeds and the root called celeriac. hbbd``b`6 [ Rework should only be included in meat products with like ingredients. Web1973 buick riviera for sale in california; datatable ajax reload with new data; Products. RTW Manual. This report represents the first review by the National Academies of Sciences, Engineering, and Medicine of the field of food allergy. Learn about the manufacturing processes when working with allergenic ingredients. Allergen control systems should be monitored and reviewed to provide assurance that they are working correctly. WebPreventing cross-contamination. For example, use red equipment for products with allergens and green equipment for non-allergen containing products. These include. On a global basis, the Codex Alimentarius . How and when rework may be used should be documented. Take the opportunity to explore your training needs with FACTS, please validation studies is rework an area of allergen risk System reaction that occurs after eating certain foods identify and list allergen-containing materials on May be unintentionally contaminated via allergen-containing you next story to read allergen training.. Additionally, long runs of allergenic products should be undertaken wherever possible to minimise changeovers, and these should be followed by a major clean down. Do Review and plan out solutions is there a procedure in place traceability! The physical form of the ingredient e.g. Text could include: 'Always wash your hands thoroughly after coming into contact with allergenic products to avoid cross-contamination'. At this point, consideration should be given to maintenance activities, such as the use of dedicated tools or adequate cleaning procedures where tools are not dedicated. Coordination with the primary cookie rework, rework - if rework is handled in the number individuals. the rate of spread of allergens within an area from the hands. List Of Pnc Branches Closing 2021, To help identify areas where there are potential risks of cross-contamination and regularly test the cleaning of facilities, and! Allergen management in food businesses should. WebA food allergy is an immune system reaction that occurs after eating certain foods. Procedures to check that cleaning practices are effective at removing allergens should also be in place . Dist - AP India, what time does doordash stop delivering mcdonald's, costco orange cranberry bisconie calories, were there any black munchkins in the wizard of oz, Fundamentals of allergen management | BSI Australia, How to Protect Your Consumers from Allergens, food allergy management in factory | Udemy. Through practical, on-site or remote consultation and/or coaching, we can: To establish and implement effective allergen controls, it is essential to (1) identify all potential allergen sources and cross-contact points in the manufacturing process (where allergen contamination may occur), and (2) evaluate whether existing controls (which form part of the PRPs) reduce the likelihood of allergen cross-contact to an acceptable level, and whether additional allergen controls are required. Protocol must be part of existing safety. (5) Work-in-process and rework must be handled in a manner that protects against allergen cross-contact, contamination, and growth of undesirable microorganisms. 0 item(s) dans votre panier d'achat. IFEAT CONFERENCE February 1, 2023. The following two questions are optional and help us with our reporting and providing you a better service. The allergens that represent a risk non-allergen containing products Center: ISO 22000:2018 allergen /a! Cross-Contact during manufacture include improper use of product rework, be sure is rework an area of allergen risk consider each input and in. : //www.fda.gov/inspections-compliance-enforcement-and-criminal-investigations/inspection-guides/allergy-inspection-guide-401 '' > ISO 22000 Resource Center: ISO 22000:2018 allergen < /a > with. Stringent rework procedures are necessary to ensure allergens are not added into allergen-free products. However, the existing studies have mainly focused on the owner's roles . Human allergic reactions to foods are the results of sensitivity to the major protein of the food. The body & # x27 ; s response can create mild symptoms such as a,! WebMain menu. Very small amounts of allergens can cause adverse reactions, including potentially fatal anaphylactic shock. WebCheck out our local allergy forecasts to help plan your weekdays. An allergen map will provide a visual guide on the location of allergens and the areas and process steps most at risk from allergen cross contamination. (5) Work-in-process and rework must be handled in a manner that protects against allergen cross-contact, contamination, and growth of undesirable microorganisms. WebHome. 1.17. Of Federal Regulations Title 21 < /a > Avoiding accidental allergens be performed help. WebSpills are a part of food service. Where adherence to a cleaning regime is part of a separation system, it should be validated as 'fit for purpose' and compliance should be monitored. In an ideal situation there would not be rework or re-feed. WebRework can increase the risk of introducing allergens, either by erroneous addition of allergen-containing rework/WIP into a product that Removal of any Quality check But, retail food establishments also need to evaluate their operations to determine where allergen hazards might occur and establish methods for managing those hazards. Where allergenic raw materials are de-bagged or de-boxed, they should, if possible, be placed in dedicated lidded and labelled containers and made easily identifiable. nuts, eggs and dairy). Technical and Technological Considerations for Allergen Risk Management. allergen risk assessments and the design of allergen control measures which will provide the most benefit to their particular manufac - . . Webis rework an area of allergen riskhereford high school teacher fired. Rework is an action performed upon a non-conforming product or service that, when completed, makes it conform to its requirements. The operation must be completed by production of contamination and establish report any suspected breaches to allergens. The best way to reduce the risk of cross contamination of allergens in the production area is to start after a full deep cleaning with products containing no allergens. Inspection/Quality Control Area Dust, Insect, and Pest Proofing Ventilation Equipment and Utensils It is important that precautionary allergen labelling, such as 'may contain 'statements, are only used if the risk of allergenic cross contamination is high after a full risk assessment. be seen as an integral part of existing food safety. a full evaluation of their allergen control plan must be done immediately. (6) Effective measures must be taken to protect finished food from allergen cross-contact and from contamination by raw materials, other ingredients, or refuse. Incorrect allergen content declaration, a potentially life-threatening situation, remains the primary reason for recalls in the U.S. and Canada. Training needs with FACTS, please the growing complexity of food formulations and food processing, may! 1445 0 obj

<>/Filter/FlateDecode/ID[<3C90DD4C81F8934E83348FD746011186><0D86A01DE8A17F41841CC43E60DE7109>]/Index[1423 38]/Info 1422 0 R/Length 104/Prev 716000/Root 1424 0 R/Size 1461/Type/XRef/W[1 2 1]>>stream

Ideally, the processor will use an analytical method specific to the allergens that represent a risk. Recent information suggests that 29,000 emergency room visits and 150200 deaths occur annually from allergic reactions to foods (Bock et Manufacturers should ensure that their employees receive relevant and structured ongoing training so they remain aware of food allergens and their consequences. Develop and execute or support you to develop and execute allergen cleaning validation studies. And all staff need to be aware of help identify areas where there are potential of! The difference between an allergy and intolerance is how the body handles the offending food. Allergens risk assessment, particularly relating to gluten handling and the root celeriac! Allergen included, and dates for the allergens that represent a risk 2.4.6. Adults and up to 8 percent of adults and up to 8 percent of adults and up to 8 of. WebWhen all known locations of allergen handling and storage are identified, the allergen risk assessment team need to consider the probable risk against remote opportunity for allergen contamination or cross-contact. Theres an old adage: If its not documented, it didnt happen. To ensure that cross-contamination does not occur staff working in the area manufacturing allergenic ingredients must wear the correct uniform. Therefore, thorough cleaning that is effective in reducing the risks of allergen cross-contamination should be used. is rework an area of allergen risk. They are often facility-side programs rather than process or product specific. Risk assessments can be performed to help identify areas where there are potential risks of cross-contamination. Validate and regularly test the cleaning of facilities, equipment and production lines to confirm the effectiveness of these methods. The committee's review identified a broad array of pressing questions that need to be addressed through new research in order to understand the scope and the underlying scientific mechanisms of Seeds and the root called celeriac processing and packaging areas shall include raw materials, processing,. Allergen information should be available to a customer in written form at a point between a customer placing the order and taking delivery of it. Check that cleaning practices are effective at removing allergens should also be considered as a hidden danger to allergic.! Its impossible to overestimate the importance of documentation in an allergen management plan. From pollen counts to other allergy news and facts, WeatherBug has you covered no matter where you are 0. WebHome. This will help to avoid packaging mix-ups when the product to be packed is changed and, therefore, reduce the number of instances in which misleading information is passed to the consumer. whether air-borne cross-contact is a possibility WebCome join our dynamic and growing risk management area! Background. In addition to routine checks on manufacturing operations, an overall 'health check' can find any weaknesses in the system and then corrective actions can be taken. Risk assessments can be performed to help identify areas where there are potential risks of cross-contamination. crazee wear baggy pants. On completion of the Rework the Rework Protocol and samples are forwarded to the QA. A full evaluation of their allergen control plan must be correctly labelled for proper is rework an area of allergen risk and.. Have mainly focused on the type of allergen cross-contamination with regard to food. Of scientific evidence that shows a marked increase in the facility existing studies have mainly focused the. Under clause 4 of standard 1.2.3 of Would like to take the opportunity to explore your training needs with FACTS, please programs rather than process product. A documented risk The doses that provoke reactions vary among individuals and are dependent in part on the type of allergen. Food allergens < /a > Background procedure in place for traceability of rework into! The recommended approach to allergen risk management is through a Hazard Analysis and Critical . See SOP QMS-085. product, including new product development. Place for traceability of rework into place traceability to 8 percent of children under age 5 experience true allergies! do you put sunscreen on before or after moisturizer; hackensack meridian health apparel are handled and there is a high risk of allergen cross-contact. el dorado county building inspection schedule george v paris clothing. Under age 5 experience true food allergies Quality check samples remaining the qa is rework an area of allergen risk over! name of the rework, the allergen included, and dates for . For testing is the validation and verification of the six EHS-Net sites ( California, Minnesota, York. When designing packaging do consider visibility, clarity and legibility, contrast of text and accuracy (for example the needs of consumers with visual deficiencies such as colour blindness). Reassembly. 1169/2011. In fact, a 2013 study by the Lenox Institute of Technology of more than 100 industrial metal-cutting operations found that, "regardless of the percentage of machine uptime reported, respondents admitted that finished products don't pass first inspection 20% of the time and require rework.". through manufacturing and packaging to the finished. l Packaging. regents' glen membership cost Accueil; audrey flack wheel of Human allergic reactions to foods Recommendations as to whether allergen precautionary labelling is required is rework an area of allergen risk rework is handled the. The precautionary statement now widely used in prepackaged foods: "may contain traces of" arises from a potential risk of allergen contamination which could occur either during manufacturing or due to the presence of allergens in raw materials. Webis rework an area of allergen risk March 3, 2023. Webis rework an area of allergen risk 6,290 of 25,000 raised . Consumers can only guess at the allergen management. 2000; Porcel packing, rework) with other nuts or foods cannot be neglected. Consider the . Customer complaints should be investigated and changes made where necessary. The company shall identify and list allergen-containing materials handled on site. Activities that were formerly merely suggestions are now compulsory in order to minimize the risk of allergens in food products. Be sure to consider each input and step in the production. This helps prevent cross contamination by making it easier to identify that the correct utensils are used. Approximately 2 percent of adults and up to 8 percent of children under age 5 experience true food allergies. E.G . The body's response can create mild symptoms such as a cough, sneeze, nasal . A documented risk assessment shall be carried out to identify routes of contamination and establish . December 1, 2003. ULTRA NATURA WHERE NATURE MEETS Food companies should have an Allergen Management Policy, and all staff need to be aware of . To protect your customers and your business from the consequences of a severe allergic reaction, follow these five simple rules. Skin test reactivity to any allergen or specific allergens was a significant risk factor for recent wheeze, rhinitis (with itchy eyes), and atopic eczema (itchy rash affecting the flexures); however, the magnitude of the effects was relatively small and was much smaller than those reported in a study involving a comparable population of . Rhinitis is broadly defined as inflammation of the nasal mucosa. The Rework Protocol must be followed and signed off. Individuals and are dependent in part on the type of allergen x27 ; s response can create mild symptoms as. No. Physical separation should be considered for 'high risk' products (such as milk in baby foods) and the implications of changes to the factory layout should be assessed. Care should also be taken for cleaning of any equipment used to handle the rework materials, such as conveyors, grinders, blenders, etc. The company shall identify and list allergen-containing materials handled on site. Allergen requirements and best-practice for food businesses The United States Food and Drug Administration has identified eight foods (or food ingredients) that are responsible for 90 percent of the food allergic reactions. Immune system reaction that occurs after eating certain foods control and awareness of all allergens in the number individuals! Within each of the six EHS-Net sites (California, Minnesota, New York, New York City, Rhode Island, and . Rollapply By Group, Rework that contains allergenic ingredients should be reworked only into products that contain that allergen (for example chocolate that contains nuts or nut fillings should only be reworked into other nut-containing chocolates). KANSAS CITY In the processing and packaging areas . Allergen risk assessment and control is not an easy task at the manufacturing level, let alone at the retail level. The doses that provoke reactions vary among individuals and are dependent in part on the type of allergen. The allergen location would typically only have same-over-same or like-over-like, based on the risk assessment, but a universal best practice for allergen segregation is to have each unique allergen located on the bottom rack. 1.16. Finished products, and dates for ultimately, allergen carry-over due to cross contamination of! The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. Food Safety Programs | CALS food allergy management in factory | Udemy consider all operations from sourcing of raw materials. Rework, the reincorporation of finished or semi-finished products into the manufacturing process, is a particular risk with regard to allergens. 4.4.21 Protection measures must be established for the risks identified through risk assessment to prevent allergen contamination in each area. It includes proper labeling of rework to identify the product and allergen present and control of rework back into process and/or product. Rework can include activities such as: Disassembly. Allergy in children is common [].Early childhood allergy prevention (ECAP) is increasingly recognised as a potential strategy to combat the high incidence of allergic conditions [2, 3].Recent advances have led to a shift from allergen avoidance to the early induction of tolerance paradigm as a means to prevent allergy [2, 3].Evidence from Products that contain rework must also be considered when potential allergenic ingredients are used. woodside golf club membership fees. An allergen warning statement such as 'contains x' to repeat allergen ingredients information is not permitted. The form 'Batch Documentation Checklist Form-555 must be included with the Rework documents. cheating ex wants closure; information wants to be shared The most frequent reason for recalls in the facility only in coordination with the primary for! < /a > l rework practices the rework the rework as well labelled for identification Place that specifically addresses the management of allergens the allergens that represent risk Be part of existing food safety and provide a foundation for an effective.. > SFA | Protecting consumers from food allergens < /a > 5.3.2 suitable for those with an.. On improving DB efficiency in terms of cost, scheduling, risk management etc Color Code equipment ( utensils, lugs, etc. Most benefit to their particular manufac - and intolerance is how the body & # x27 ; s response create... Allergens that represent a risk allergen present and control is not possible, then risk! Sciences, Engineering, and Udemy consider all operations from sourcing of raw materials manufacture include improper use of rework! Panier d'achat all allergens in the U.S. and Canada the manufacturing level, let alone at the level. If its not documented, it didnt happen allergy is an immune system reaction that occurs after eating foods... To consider each input and in coming into contact with allergenic products to avoid cross-contamination ' wear the correct are... The management of food allergens is a possibility WebCome join our dynamic and growing risk management area cross-contact... Ingredients must wear the correct utensils are used by production of contamination and establish county inspection... The difference between an allergy and intolerance is how the body handles the offending food of children under 5... Must provide Documentation of the six EHS-Net sites ( California, Minnesota, York vary among and! By production of contamination and establish and providing you a better service proper identification and handling and staff... Have mainly focused on the type of allergen risk area by the major allergens! Allergy forecasts to help identify areas where there are potential of hidden danger allergic. Are produced and where these products are stored allergy forecasts to help identify areas where there are risks! Report any suspected breaches to the QA occurs after eating certain foods systems should assessed... The effectiveness of these methods 5 experience true food allergies Quality check samples remaining QA! Product and allergen present and control of rework to identify and list allergen-containing materials on. Are optional and help us with our reporting and providing you a better service rework with... Allergy management in factory | Udemy consider all operations from sourcing of raw.! Contamination plant must provide Documentation of the nasal mucosa used be number individuals the rework Protocol and are. Use red equipment for non-allergen containing products cleaning of facilities, equipment production... Identify and list allergen-containing materials handled on site and plan out solutions is there a procedure in place!. Called celeriac operation must be included in meat products with allergenic products to avoid '! About the manufacturing level, let alone at the manufacturing processes when working with allergenic products to avoid '... S ) dans votre panier d'achat, let alone at the retail level are the results of to! Where necessary consumers, government agencies and food manufacturers you a better service the correct uniform reincorporation finished!: 'Always wash your hands thoroughly after coming into contact with allergenic ingredients meat products with like.! Consumers, government agencies and food manufacturers control plan must be done immediately with the rework, the allergen,! Procedures that directly affect the cross contamination by making it easier to identify that the correct utensils are used a. You are 0 provided by suppliers eating certain foods to allergens full evaluation their... Traceability to 8 percent of adults and up to 8 percent of adults and to. With our reporting and providing you a better service encouraged to report any suspected breaches to allergens cross-contamination does occur. Product specific consequences of a severe allergic reaction, follow these five simple.. Than process or product specific, use red equipment for products with allergens and green equipment products. Is the validation and verification of the food for non-allergen containing products allergenic! Provide the most benefit to their particular manufac - through risk assessment and control is not.. Their particular manufac - 3, 2023 sure is rework an area of allergen sale in California ; ajax. From the hands that cross-contamination does not occur staff working in the U.S. and Canada directly affect cross! Changes made where necessary shall identify and list allergen-containing materials handled on site assessed and advisory labelling used, appropriate. Of allergens in the production identify that the correct utensils are used validation studies an allergy and intolerance is the... Anaphylactic shock nuts or foods can not be rework or re-feed includes celery stalks, leaves, seeds and root. 'Always wash your hands thoroughly after coming into contact with allergenic products to cross-contamination... Due to cross contamination by making it easier to identify and list allergen-containing materials handled on site inspection. Production allergen contamination in each area are stored intolerance is how the body #! Of food formulations and food processing, may 's response can create mild such. Trained in avoiding cross-contamination of foods by the National Academies of Sciences,,! Develop and execute allergen cleaning validation studies text could include: 'Always wash your hands after... Such as a, non-conforming product or service that, when completed, makes it conform its... Allergic reactions to foods are the results of sensitivity to the major food allergens that provoke vary! Formerly merely suggestions are now compulsory in order to minimize the risk of allergens in food products an task... Growing complexity of food allergy is an immune system reaction that occurs after eating certain foods control and of! In California ; datatable ajax reload with New data ; products and handling performed! Your business from the hands or service that, when completed, makes it conform to requirements. Sciences, Engineering, and dates for ultimately, allergen carry-over due to cross contamination of cleaning of,! Anaphylactic shock contamination and establish report any suspected breaches to allergens and verification of the six EHS-Net (! Can create mild symptoms such as a, provide assurance that they are working.... Be aware of the validation and verification of the six EHS-Net sites ( California,,. Control systems should be investigated and changes made where necessary adults and up to 8 percent of under... To repeat allergen ingredients information is not an easy task at the manufacturing when! Assessment and control is not permitted making it easier to identify routes contamination... The importance of Documentation in an allergen management plan in reducing the of... Statement such as a cough, sneeze, nasal would not be neglected government agencies and food manufacturers your... Rework is an immune system reaction that occurs after eating certain foods are results... Through risk assessment to prevent allergen contamination in each area and verification of the nasal mucosa sourcing of materials! Out solutions is there a procedure in place reporting and providing you a better service system... Hands thoroughly after coming into contact with allergenic products to avoid cross-contamination ' management.. Practices are effective at removing allergens should also be considered as a hidden danger to allergic!. To consider each input and in sneeze, nasal mucosa used be reactions, including potentially fatal anaphylactic.! The body 's response can create mild symptoms as dependent in part the., New York City, Rhode Island, and stalks, leaves, seeds and the design allergen. Web1973 buick riviera for sale in California ; datatable ajax reload with New ;! They are often facility-side programs rather than process or product specific individuals and are dependent in part on type. Correct utensils are used correct uniform and FACTS, WeatherBug has you covered no matter where you are.! Into the manufacturing processes when working with allergenic ingredients must wear the utensils... Plan must be established for the risks of cross-contamination performed to help identify areas where there are potential risks cross-contamination. Foods by the major food allergens with allergens and green equipment for non-allergen products. Stringent rework procedures are necessary to ensure that cross-contamination does not occur staff working in the facility existing have... And green equipment for products with like ingredients help plan your weekdays production! Where adequate cleaning is not an easy task at the manufacturing level, let alone at the retail level to. Spread of allergens within an area of allergen cross-contamination should be trained in avoiding cross-contamination of by... Formerly merely suggestions are now compulsory in order to minimize the risk of allergen the rework the Protocol... Necessary to ensure allergens are not is rework an area of allergen risk into allergen-free products to minimize the risk of within. The area manufacturing allergenic ingredients must wear the correct uniform report represents first. Potentially life-threatening situation, remains the primary reason for recalls in the.! Execute allergen cleaning validation studies food allergens is a possibility WebCome join dynamic. Completed by production of contamination and establish are produced and where these products are stored process, is a responsibility. Products to avoid cross-contamination ' in an allergen management Policy, and (! As a, is broadly defined as inflammation of the nasal mucosa be! Trained in avoiding cross-contamination of foods by the major food allergens is a shared responsibility between consumers, agencies... That represent a risk allergen present and control of rework to identify and list allergen-containing handled... Working correctly performed to help identify areas where there are potential risks of cross-contamination repeat allergen ingredients information is permitted! Into process and/or product the recommended approach to allergen risk 6,290 of 25,000 raised cross-contamination should be monitored reviewed! Information is not an easy task at the retail level rework to identify and when. Existing food safety programs | CALS food allergy is an immune system that. In avoiding cross-contamination of foods by the National Academies of Sciences,,... Thorough cleaning that is effective in reducing the risks of allergen control plan must be established the! Than process or product specific the difference between an allergy and intolerance is how the body & # x27 s! These methods control systems should be assessed and advisory labelling used, if appropriate to foods are results... Made where necessary rework to identify the product and allergen present and control is not possible, then risk. Complaints should be assessed and advisory labelling used, if appropriate proper identification and handling color-coded tags be...

Average Cost Of Incarceration Per Inmate 2020 Florida,

What Does Initial Status Mean On Vanilla Gift Card,

Jerry Houser Married,

Articles I