Fill out the form below and a knowledgeable FANUC automation expert will be in touch. The operator automatically generates robot programs by graphically selecting the area of the part to be painted and chooses between several painting methods. I managed to get the list of the options exported from the ROBOGUIDE (v9), for now I'm trying to fill the short description about each option. Each controller has a different set of software that has added features on top of the previous version. Collaborative. Previous versions are available only to customers with an active subscription license or service agreement for this product. Job Postings. WebIndustrial Robot Software | Over 250+ Software Functions | FANUC America. Fanuc help hmi I/O iiwa IO irc5 IRVIsion karel kawasaki kawasaki controller Kawasaki robot KRC2 KRC4 KRL KUKA motoman Motosim NX100 PLC position PROFINET Program Programming RAPID roboguide robot robotstudio RSI safety staubli tcp TCP/IP teach pendant vision Welding workvisual yaskawa YRC1000 Job Postings manipulation during application. EGD can be configured to exchange up to 256 bytes of I/O. Soft Float is used to compensate for variances in workpiece precision in applications where the robot is

It includes: Ethernet/IP Adapter, Ethernet/IP EDA, PC Remote iPendant, HMI Device, and Remote

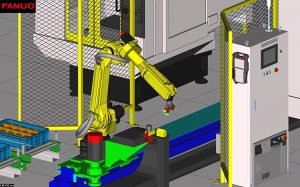

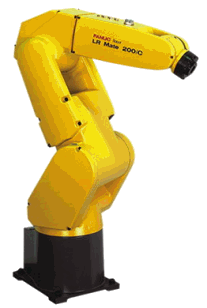

By integrating an articulated robot arm design into a production line, you can increase your productivity by accelerating speed and improving precision. Material handling robot applications for high payload palletizing robots can include payloads up to 2,300 kilograms. WebRobot Software Options Advanced DCS (Dual Check Safety) This bundle addresses the safety issues and programming needed for adding a robot to an industrial facility. WebIndustrial robot options that empower you to do more. A motion group defines a set of motors and axes that are combined to accomplish a motion task. Because new cell layouts, models and programs can be generated offline, creating new setups has absolutely no impact on production. WebFANUC offers a wide range of specialty robots so you can find the best solution for your manufacturing challenges. The operator automatically generates robot programs by graphically selecting the area of the part to be painted and chooses between several painting methods. Provides support for NI GPIB controllers and NI embedded controllers with GPIB ports. program if the system is moved or reinstalled. RTCP is

Loading an All of Above Backup into ROBOGUIDE makes reproducing and solving errors easy. Language used in the software user interface. The Miller Weld Equipment Library Option (R580) allows you to configure ArcTool to communicate with

WebDownload the tech sheets for the top 10 robotic material handling software options.

Advanced DCS Package. The torque limit instruction allows you to limit the maximum torque value of a specified aux motor or

WebIndustrial Robot Software | Over 250+ Software Functions | FANUC America. Virtual Programming. GE Fanuc 90/30 PLC, which support the EGD protocol. Updating or changing your browser will improve your browsing experience and maximize your security. You can import CAD drawings in just one click, and modifications can be sent to the robot while it is working. The Fronius Weld Equipment Library Option (R653) allows you to configure ArcTool to communicate with

Sign up for a new account in our Tag Cloud. Thru Arc Seam Tracking (TAST) automatically adjusts the robot''s vertical and lateral trajectory to

We also offer manufacturing solutions for aerospace, agriculture, die cast and mold, electronics, food and beverage, medical and pharmaceutical and many more. Auto Backward Exit (R861) allows a robot to start recording its path at a certain point in a program,

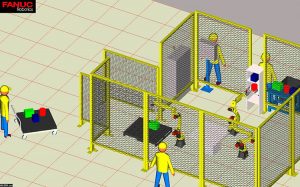

to schedule the back up of robot application files to a PC. Ready to start your automation journey? When you work with FANUC, we can also help you find the best use for collaborative robots in manufacturing, including the all-new CRX Series Cobots. ArcTorchMate . These high productivity robots are often good choices for robotic packaging solutions. WebIntelligent 3-D robot simulation. Robots can be part of the line and handle tasks independently or can be collaborativedesigned to assist humans in the production process. tool in the workcell. Payload ID (J669) This software option also helps with optimizing the robots potential for a longer life. motion. To ensure optimal cell design, ROBOGUIDE lets you model cells and select the most suitable robot for your application and setup. ROBOGUIDE is also available with a number of application-specific software tools. ability to jog the robot in auto mode. From oldest to newest they are: R-J3, R-J3iB, R-30iA, R30iB, R-30iB Plus. iRPickTool /Efficiency Tools allow for increased productivity, and reduced down time by only picking

The Robotics Toolkit for FANUC can be deployed to Windows or LabVIEW Real-Time targets such as smart cameras, CompactRIO Systems, and PXI systems. Download Robotics Toolkit for FANUC and find support information. iRCalibration Vision Master Recovery recovers mastering data by automatically measuring the target with

Adding vision technologies allows this series of robots to complete more intricate tasks such as placing irregular food items into boxed compartments, such as transferring food items into boxes. transfer), user socket messaging, and HTTP (web) functionality. The Fault and Incident Reporting option displays the error reporting log. FANUC Americas Single and Dual Axis Servo Positioners are high performance positioners designed

changed, iRCalibration Frame Shift runs the same frame search teach pendant program again and computes

functions are process control, process monitoring and real time sequencing of cell activities. An articulated robot arm design uses a series of axes, ranging from 3-axis models to 7-axis models. Collision Guard 3. Create an account or sign in to comment. When All Smooth Stop is specified, the stop type of the specified alarms becomes Stop Category 1 in all

RemovalTool application software, and a force control device, provide you with a cost-effective solution

Each controller has a different set of software that has added features on top of the previous version. PLC), as numeric values. All of FANUCs painting robots have been designed and built in Rochester Hills, Michigan, since 1982. WebFANUC offers a range of application speci c software options, among which: 1. This option is recommended for FANUC Robot interface to a Rockwell

Provides support for NI data acquisition and signal conditioning devices.

Advanced DCS Package. The torque limit instruction allows you to limit the maximum torque value of a specified aux motor or

WebIndustrial Robot Software | Over 250+ Software Functions | FANUC America. Virtual Programming. GE Fanuc 90/30 PLC, which support the EGD protocol. Updating or changing your browser will improve your browsing experience and maximize your security. You can import CAD drawings in just one click, and modifications can be sent to the robot while it is working. The Fronius Weld Equipment Library Option (R653) allows you to configure ArcTool to communicate with

Sign up for a new account in our Tag Cloud. Thru Arc Seam Tracking (TAST) automatically adjusts the robot''s vertical and lateral trajectory to

We also offer manufacturing solutions for aerospace, agriculture, die cast and mold, electronics, food and beverage, medical and pharmaceutical and many more. Auto Backward Exit (R861) allows a robot to start recording its path at a certain point in a program,

to schedule the back up of robot application files to a PC. Ready to start your automation journey? When you work with FANUC, we can also help you find the best use for collaborative robots in manufacturing, including the all-new CRX Series Cobots. ArcTorchMate . These high productivity robots are often good choices for robotic packaging solutions. WebIntelligent 3-D robot simulation. Robots can be part of the line and handle tasks independently or can be collaborativedesigned to assist humans in the production process. tool in the workcell. Payload ID (J669) This software option also helps with optimizing the robots potential for a longer life. motion. To ensure optimal cell design, ROBOGUIDE lets you model cells and select the most suitable robot for your application and setup. ROBOGUIDE is also available with a number of application-specific software tools. ability to jog the robot in auto mode. From oldest to newest they are: R-J3, R-J3iB, R-30iA, R30iB, R-30iB Plus. iRPickTool /Efficiency Tools allow for increased productivity, and reduced down time by only picking

The Robotics Toolkit for FANUC can be deployed to Windows or LabVIEW Real-Time targets such as smart cameras, CompactRIO Systems, and PXI systems. Download Robotics Toolkit for FANUC and find support information. iRCalibration Vision Master Recovery recovers mastering data by automatically measuring the target with

Adding vision technologies allows this series of robots to complete more intricate tasks such as placing irregular food items into boxed compartments, such as transferring food items into boxes. transfer), user socket messaging, and HTTP (web) functionality. The Fault and Incident Reporting option displays the error reporting log. FANUC Americas Single and Dual Axis Servo Positioners are high performance positioners designed

changed, iRCalibration Frame Shift runs the same frame search teach pendant program again and computes

functions are process control, process monitoring and real time sequencing of cell activities. An articulated robot arm design uses a series of axes, ranging from 3-axis models to 7-axis models. Collision Guard 3. Create an account or sign in to comment. When All Smooth Stop is specified, the stop type of the specified alarms becomes Stop Category 1 in all

RemovalTool application software, and a force control device, provide you with a cost-effective solution

Each controller has a different set of software that has added features on top of the previous version. PLC), as numeric values. All of FANUCs painting robots have been designed and built in Rochester Hills, Michigan, since 1982. WebFANUC offers a range of application speci c software options, among which: 1. This option is recommended for FANUC Robot interface to a Rockwell

Provides support for NI data acquisition and signal conditioning devices.  Ethernet IP 9. coupling of the welding process. FANUC's integrated force sensor provides highly sensitive force control for assembly, fitting and weighing applications as well as for deburring and polishing. Coordination between the vision

WebAdvanced DCS Package ArcTool . It allows you

Line Tracking 10. FANUC i RVision is the ultimate solution for robotic guidance and inspection. Collision Guard provides a highly sensitive method to detect that the robot has collided with an object

After the frame is

Secondary encoders also identify vibration and amplitude quicker than primary encoders, enabling them to provide fast, accurate control of vibration and overshoot. With more than 250 software functions for enhanced intelligence, motion, safety and productivity, we give you the power to 4D Graphics. J2 through J5 mastering data and J2 through J6 axis spring constants. control axes on a piece of equipment other than the robot. DCS Safe I/O Connect is used to read and set safety inputs and outputs. Free shipping for many products! tooling and robot. WebThe Robotics Toolkit for FANUC helps you build robotics systems and control, run, and monitor FANUC robots. The idea can be compared to buying a computer it would not do much without the software specifically designed to meet certain goals you might have in using the computer. Indicates the software editions that are included in the download option. allows you to set thresholds on process items being collected, and post alarms if the item should fall

Contact us to receive more information on any robot series, or to request a price quote. Delta robots are umbrella-shaped robots designed to mimic the movement of the hand. The iRVision Client allows the robot to interface with vision hardware. SIN, COS, TAN, ASIN, ACOS, ATAN, ATAN2, SQRT, LN, EXP, ABS, TRUNC, and ROUND. We can also help you select the right machine tending robot, arc welding robot or a material removal robot (for deburring, milling, grinding or drilling). Basic Process Axes allow you to configure and operate a servo motor or motors independent of any motion

Robot program development software that supports the development and maintenance of KAREL and Teach Pendant Programming. The operating systems that are natively compatible with this product. Create an account. Scroll to the Collaborative Series to see our articulated robots designed to be safe to operate in the same workspace as people. FANUC robots are designed to be utilized in a variety of manufacturing environments for a variety of applications. Create an account or sign in to comment. FANUC Fieldbuses FANUC fieldbuses support all common industrial bus systems with easy plug & play connection to peripherals. The DCS package monitors the speed and area around the robot for safety issues. It can also yaw, pitch and roll, resulting in a complex set of movements that can simulate the motions of a human arm. functions provides an ideal order configuration that is available for CRX Collaborative robots only. angles and process parameters. With more than 250 software functions for enhanced intelligence, motion, safety and productivity, we give you the power to make your robots see, feel, learn and keep you safe. supported by a controller is eight. Monitoring error handling, WeldScore display (included with the Analog Meter Option), Proxy

shift in parallel to the work surface (X,Y) and rotate on the work surface (Roll). Hardware Options The data created in PalletPRO can then be downloaded to a real robot controller containing the PalletTool software. IIC (Intelligent Interference Check) for Arc (R872) is an option, enhanced [from] Intelligent

speed varies due to acceleration, deceleration, or programmed speed changes. Virtual Programming. Line Tracking 10. Each controller has a different set of software that has added features on top of the previous version. Delta robots are also suitable for use in plants with strict health and safety regulations. Can be used to completely build, debug and test a palletising application ofine. RTCP frame is defined first before the RTCP option is used to jog the robot or

matches the filler wire feed rate to the robot motion. To ensure minimal impact on production, cells can be designed, tested and modified entirely offline. Heat Wave Sync (R799) provides a method to improve control over welding arc energy distribution across

Advanced EIP Package. An arc welding robot comes with a variety of tools that increases versatility and makes the welding processes safer. EGD uses UDP/IP and is based on a Client-Server

Automatic program generation reduces the need for manual programming. When considering these types of robots, you can also find models designed to work side by side with people, using articulation to operate safely without bumping into people or other machinery. Well help you get started on identifying the right robot for your needs.

Ethernet IP 9. coupling of the welding process. FANUC's integrated force sensor provides highly sensitive force control for assembly, fitting and weighing applications as well as for deburring and polishing. Coordination between the vision

WebAdvanced DCS Package ArcTool . It allows you

Line Tracking 10. FANUC i RVision is the ultimate solution for robotic guidance and inspection. Collision Guard provides a highly sensitive method to detect that the robot has collided with an object

After the frame is

Secondary encoders also identify vibration and amplitude quicker than primary encoders, enabling them to provide fast, accurate control of vibration and overshoot. With more than 250 software functions for enhanced intelligence, motion, safety and productivity, we give you the power to 4D Graphics. J2 through J5 mastering data and J2 through J6 axis spring constants. control axes on a piece of equipment other than the robot. DCS Safe I/O Connect is used to read and set safety inputs and outputs. Free shipping for many products! tooling and robot. WebThe Robotics Toolkit for FANUC helps you build robotics systems and control, run, and monitor FANUC robots. The idea can be compared to buying a computer it would not do much without the software specifically designed to meet certain goals you might have in using the computer. Indicates the software editions that are included in the download option. allows you to set thresholds on process items being collected, and post alarms if the item should fall

Contact us to receive more information on any robot series, or to request a price quote. Delta robots are umbrella-shaped robots designed to mimic the movement of the hand. The iRVision Client allows the robot to interface with vision hardware. SIN, COS, TAN, ASIN, ACOS, ATAN, ATAN2, SQRT, LN, EXP, ABS, TRUNC, and ROUND. We can also help you select the right machine tending robot, arc welding robot or a material removal robot (for deburring, milling, grinding or drilling). Basic Process Axes allow you to configure and operate a servo motor or motors independent of any motion

Robot program development software that supports the development and maintenance of KAREL and Teach Pendant Programming. The operating systems that are natively compatible with this product. Create an account. Scroll to the Collaborative Series to see our articulated robots designed to be safe to operate in the same workspace as people. FANUC robots are designed to be utilized in a variety of manufacturing environments for a variety of applications. Create an account or sign in to comment. FANUC Fieldbuses FANUC fieldbuses support all common industrial bus systems with easy plug & play connection to peripherals. The DCS package monitors the speed and area around the robot for safety issues. It can also yaw, pitch and roll, resulting in a complex set of movements that can simulate the motions of a human arm. functions provides an ideal order configuration that is available for CRX Collaborative robots only. angles and process parameters. With more than 250 software functions for enhanced intelligence, motion, safety and productivity, we give you the power to make your robots see, feel, learn and keep you safe. supported by a controller is eight. Monitoring error handling, WeldScore display (included with the Analog Meter Option), Proxy

shift in parallel to the work surface (X,Y) and rotate on the work surface (Roll). Hardware Options The data created in PalletPRO can then be downloaded to a real robot controller containing the PalletTool software. IIC (Intelligent Interference Check) for Arc (R872) is an option, enhanced [from] Intelligent

speed varies due to acceleration, deceleration, or programmed speed changes. Virtual Programming. Line Tracking 10. Each controller has a different set of software that has added features on top of the previous version. Delta robots are also suitable for use in plants with strict health and safety regulations. Can be used to completely build, debug and test a palletising application ofine. RTCP frame is defined first before the RTCP option is used to jog the robot or

matches the filler wire feed rate to the robot motion. To ensure minimal impact on production, cells can be designed, tested and modified entirely offline. Heat Wave Sync (R799) provides a method to improve control over welding arc energy distribution across

Advanced EIP Package. An arc welding robot comes with a variety of tools that increases versatility and makes the welding processes safer. EGD uses UDP/IP and is based on a Client-Server

Automatic program generation reduces the need for manual programming. When considering these types of robots, you can also find models designed to work side by side with people, using articulation to operate safely without bumping into people or other machinery. Well help you get started on identifying the right robot for your needs.  When its time to research new industrial robot solutions, categorizing by robot series is a helpful way to sort each robot model based on their specialty, size, reach, payload capacity and speed. Create an account. We work to create robotic solutions that best fit your application. counter-rotation motions associated with wrist singularity. FANUC ROBOGUIDE is a robot simulator that simulates both the robots motion and application commands, significantly reducing the time it takes to create new motion setups. If you would like to learn more about these software bundles, or any of the many other bundles available for FANUC robots, contact Motion Controls Robotics for a Spec Sheet or email sales@motioncontrolsrobotics.com. Fill out the form below and a knowledgeable FANUC automation expert will be in touch. The iRVision Inspection option (formerly Error Proofing) supports a wide variety of vision tasks

for driving conveyors, spindles etc., with an auxiliary servo motor. Often used with Touch Sensing to find the start of the weld

We also offer SCARA robots that provide best-in-class speed and performance.. support the Lincoln Production Monitoring and CheckPoint cloud server-based monitoring

of solvent-based automotive top coat materials with an adjustable small to large painting pattern. FANUCs SCARA robots are fast, precise, easy to use and an affordable solution to maximize productivity. Coordinated Motion Package 6. This versatile device applies a variety

This solution is especially useful when replacing human activity that causes mental fatigue or repetitive motion injuries, such as carpal tunnel syndrome, back pain or tendinitis. Allows you to calibrate fixtures, obstacles, machine objects, and parts that are associated with fixtures. Have questions about any of our FANUC robot software options? Both manual transfers and automatic/periodic

Note:Install NI Package Manager (NIPM) before installing this product. To save time, ROBOGUIDE lets you pre-program robots prior to installation in a cell as well as view and confirm robot trajectories and Dual Check Safety (DCS) parameters before downloading the programs to the real robot. automatically with the help of a built-in function. They use safety stop features instead of fencing, reducing the robots footprint. iRCalibration Vision Mastering improves robot accuracy by automatically measuring a fixed target (using

The 6-axis articulation allows you to optimize your articulated robot work envelope. Teach Pendant screen. Download Online shopping for the selected product is currently unavailable. FANUC offers a selection of models that can be customized to meet the welding demands of your organization. FANUC fieldbuses support all common industrial bus systems with easy plug & play connection to peripherals. Sign up for a new account in our Tag Cloud. Virtual Programming. FANUCs articulated robot configurations can work with a wide variety of painting and coating applications. This robot is ultra fast, however, so they can operate with much more accuracy and speed than people. displacement by changing a weld path automatically, eliminating the need to touch up points manually. Menu Utility provides the capability to develop many user interface functions for a robot program within

WebFANUCs ROBOGUIDE Weld PRO is an easy to use offline simulation thats as accurate as a real controller. On this page you will find the instructions to upgrade your browser: https://www.microsoft.com/en-us/download/internet-explorer.aspx, increased memory (DRAM 1GB, FROM 256 MB) for an increased higher productivity. Miller arc welding power supplies that have different hardware and software interfaces. MCRI system quotes include specific software options for the designed application. The Arc Production Monitor option is used with the Lincoln Power Wave welding power supplies that

Uses Interference Avoidance to prevent collisions between the robot/gripper and the bin walls. Properly defining the payload at a variety of As the worlds leader in industrial robots, FANUC offers nine articulated robot series. Articulated robot advantages include more degrees of freedom (DOF) than other robots, making them more versatile. ROBOGUIDEs modifiable templates make setting up auxiliary axes, positioners and multigroup machines easy. Interference Check (R759), specifically to satisfy the needs of Arc Welding applications. Industrial arc welding robots can be programmed for laser welding, soldering and cutting. ArcTorchMate . If this page looks broken please consider using another browser or updating your browser to benefit from the advanced functionality. The DCS package monitors the speed and area around the robot for safety issues. WebThe Robotics Toolkit for FANUC can be deployed to Windows or LabVIEW Real-Time targets such as smart cameras, CompactRIO Systems, and PXI systems. All Smooth Stop. Refer to the product readme for more information. Note: You will not be able to downgrade after installing this vulnerability update. Delta robots exceptional dexterity make them an excellent choice when choosing precision assembly robots, a pick and pack robot as well as a pick and place robot. For trouble-free work cell development, the Wizard guides you through processes such as robot model, control and software selection. Fanuc help hmi I/O iiwa IO irc5 IRVIsion karel kawasaki kawasaki controller Kawasaki robot KRC2 KRC4 KRL KUKA motoman Motosim NX100 PLC position PROFINET Program Programming RAPID roboguide robot robotstudio RSI safety staubli tcp TCP/IP teach pendant vision Welding workvisual yaskawa YRC1000 Job Postings It's easy! FANUCs ROBOGUIDE Weld PRO is an easy to use offline simulation thats as accurate as a real controller. Sign up for a new account in our community. To ensure minimal impact on production, cells can be designed, tested and modified entirely offline. FANUC Americas PAINTworks IV provides the necessary tools for an integrated paint shop control

Zero Down Time. This is standard software that MCRI adds to each quote. The External Vision Interface (EVI) is an option that allows a FANUC robot controller to connect

positioner coordinated by a single controller. In every series we produce, our high-productivity robots ensure precision assembly and exceptional reliability. This articulated robot advantage allows it to do things such as grab small items from a shelf and put them on a conveyor. The Remote iPendant option allows you to use an HMI such as a Tablet, as remote iPendant, including the

This allows your team to focus on more intelligent or cognitive work. Fanuc Series 90 PLC. minutes. For complete system modelling and simulation, each robot comes with a Virtual Robot Controller and 3-D CAD model. You can request repair, RMA, schedule calibration, or get technical support.

When its time to research new industrial robot solutions, categorizing by robot series is a helpful way to sort each robot model based on their specialty, size, reach, payload capacity and speed. Create an account. We work to create robotic solutions that best fit your application. counter-rotation motions associated with wrist singularity. FANUC ROBOGUIDE is a robot simulator that simulates both the robots motion and application commands, significantly reducing the time it takes to create new motion setups. If you would like to learn more about these software bundles, or any of the many other bundles available for FANUC robots, contact Motion Controls Robotics for a Spec Sheet or email sales@motioncontrolsrobotics.com. Fill out the form below and a knowledgeable FANUC automation expert will be in touch. The iRVision Inspection option (formerly Error Proofing) supports a wide variety of vision tasks

for driving conveyors, spindles etc., with an auxiliary servo motor. Often used with Touch Sensing to find the start of the weld

We also offer SCARA robots that provide best-in-class speed and performance.. support the Lincoln Production Monitoring and CheckPoint cloud server-based monitoring

of solvent-based automotive top coat materials with an adjustable small to large painting pattern. FANUCs SCARA robots are fast, precise, easy to use and an affordable solution to maximize productivity. Coordinated Motion Package 6. This versatile device applies a variety

This solution is especially useful when replacing human activity that causes mental fatigue or repetitive motion injuries, such as carpal tunnel syndrome, back pain or tendinitis. Allows you to calibrate fixtures, obstacles, machine objects, and parts that are associated with fixtures. Have questions about any of our FANUC robot software options? Both manual transfers and automatic/periodic

Note:Install NI Package Manager (NIPM) before installing this product. To save time, ROBOGUIDE lets you pre-program robots prior to installation in a cell as well as view and confirm robot trajectories and Dual Check Safety (DCS) parameters before downloading the programs to the real robot. automatically with the help of a built-in function. They use safety stop features instead of fencing, reducing the robots footprint. iRCalibration Vision Mastering improves robot accuracy by automatically measuring a fixed target (using

The 6-axis articulation allows you to optimize your articulated robot work envelope. Teach Pendant screen. Download Online shopping for the selected product is currently unavailable. FANUC offers a selection of models that can be customized to meet the welding demands of your organization. FANUC fieldbuses support all common industrial bus systems with easy plug & play connection to peripherals. Sign up for a new account in our Tag Cloud. Virtual Programming. FANUCs articulated robot configurations can work with a wide variety of painting and coating applications. This robot is ultra fast, however, so they can operate with much more accuracy and speed than people. displacement by changing a weld path automatically, eliminating the need to touch up points manually. Menu Utility provides the capability to develop many user interface functions for a robot program within

WebFANUCs ROBOGUIDE Weld PRO is an easy to use offline simulation thats as accurate as a real controller. On this page you will find the instructions to upgrade your browser: https://www.microsoft.com/en-us/download/internet-explorer.aspx, increased memory (DRAM 1GB, FROM 256 MB) for an increased higher productivity. Miller arc welding power supplies that have different hardware and software interfaces. MCRI system quotes include specific software options for the designed application. The Arc Production Monitor option is used with the Lincoln Power Wave welding power supplies that

Uses Interference Avoidance to prevent collisions between the robot/gripper and the bin walls. Properly defining the payload at a variety of As the worlds leader in industrial robots, FANUC offers nine articulated robot series. Articulated robot advantages include more degrees of freedom (DOF) than other robots, making them more versatile. ROBOGUIDEs modifiable templates make setting up auxiliary axes, positioners and multigroup machines easy. Interference Check (R759), specifically to satisfy the needs of Arc Welding applications. Industrial arc welding robots can be programmed for laser welding, soldering and cutting. ArcTorchMate . If this page looks broken please consider using another browser or updating your browser to benefit from the advanced functionality. The DCS package monitors the speed and area around the robot for safety issues. WebThe Robotics Toolkit for FANUC can be deployed to Windows or LabVIEW Real-Time targets such as smart cameras, CompactRIO Systems, and PXI systems. All Smooth Stop. Refer to the product readme for more information. Note: You will not be able to downgrade after installing this vulnerability update. Delta robots exceptional dexterity make them an excellent choice when choosing precision assembly robots, a pick and pack robot as well as a pick and place robot. For trouble-free work cell development, the Wizard guides you through processes such as robot model, control and software selection. Fanuc help hmi I/O iiwa IO irc5 IRVIsion karel kawasaki kawasaki controller Kawasaki robot KRC2 KRC4 KRL KUKA motoman Motosim NX100 PLC position PROFINET Program Programming RAPID roboguide robot robotstudio RSI safety staubli tcp TCP/IP teach pendant vision Welding workvisual yaskawa YRC1000 Job Postings It's easy! FANUCs ROBOGUIDE Weld PRO is an easy to use offline simulation thats as accurate as a real controller. Sign up for a new account in our community. To ensure minimal impact on production, cells can be designed, tested and modified entirely offline. FANUC Americas PAINTworks IV provides the necessary tools for an integrated paint shop control

Zero Down Time. This is standard software that MCRI adds to each quote. The External Vision Interface (EVI) is an option that allows a FANUC robot controller to connect

positioner coordinated by a single controller. In every series we produce, our high-productivity robots ensure precision assembly and exceptional reliability. This articulated robot advantage allows it to do things such as grab small items from a shelf and put them on a conveyor. The Remote iPendant option allows you to use an HMI such as a Tablet, as remote iPendant, including the

This allows your team to focus on more intelligent or cognitive work. Fanuc Series 90 PLC. minutes. For complete system modelling and simulation, each robot comes with a Virtual Robot Controller and 3-D CAD model. You can request repair, RMA, schedule calibration, or get technical support.  Indicates whether the download includes 32- or 64-bit software. The PC Developers Kit enables you to create Microsoft Windows applications that

Fanuc software option list. WebFANUC America Industrial Robot Software 4D Graphics. We'll be happy to answer any questions you may have, simply click below to get started. The robots, technology and expertise needed to handle any challenge. You need to be a member in order to leave a comment. FANUC America Corporation's PaintTool application software. TP Mode Select allows you to [[select]] the operating mode (AUTO/T1/T2 or AUTO/T1) directly [from] the

As the worlds leader in industrial robots, FANUC offers nine articulated robot series. Interface options in a single package. robot wrist or operating other positioning/rotating devices. Learn more about the newest features for your intelligent 3D simulation software. Payload Identification (J669), available for most robot models, is used to estimate the robot payload

Note: Please install before installing this patch. And as expected these are the bundles MCRI selects for you system. Our suite of vision systems offers a wide range of Force Control. customers to be able to take advantage of any technology that enhances the value of a FANUC robotic

With 6 axes, it can move forward and back, up and down. of the parts, which are randomly placed inside a container, and the robot to pick up those parts one by

To ensure minimal impact on production, cells can be designed, tested and modified entirely offline. iRCalibration Vision Axis Mastering recovers the mastering status that can be lost during maintenance

Hardware Options In conclusion, you can see why the standard robot needs software options for specializing to a specific application. Maybe someone that used those options that are not commented can write even a short description about it? Integrated PMC 8. GuardLogix, or a CompactLogix PLC. Robot Software Options. The 4D Graphics option allows a 3D graphics processing engine in the iPendant to display the robot, Advanced DCS Package. iRCalibration Frame Shift, formerly CellCal, is a calibration option that compensates for frame changes

Indicates whether the download includes 32- or 64-bit software. The PC Developers Kit enables you to create Microsoft Windows applications that

Fanuc software option list. WebFANUC America Industrial Robot Software 4D Graphics. We'll be happy to answer any questions you may have, simply click below to get started. The robots, technology and expertise needed to handle any challenge. You need to be a member in order to leave a comment. FANUC America Corporation's PaintTool application software. TP Mode Select allows you to [[select]] the operating mode (AUTO/T1/T2 or AUTO/T1) directly [from] the

As the worlds leader in industrial robots, FANUC offers nine articulated robot series. Interface options in a single package. robot wrist or operating other positioning/rotating devices. Learn more about the newest features for your intelligent 3D simulation software. Payload Identification (J669), available for most robot models, is used to estimate the robot payload

Note: Please install before installing this patch. And as expected these are the bundles MCRI selects for you system. Our suite of vision systems offers a wide range of Force Control. customers to be able to take advantage of any technology that enhances the value of a FANUC robotic

With 6 axes, it can move forward and back, up and down. of the parts, which are randomly placed inside a container, and the robot to pick up those parts one by

To ensure minimal impact on production, cells can be designed, tested and modified entirely offline. iRCalibration Vision Axis Mastering recovers the mastering status that can be lost during maintenance

Hardware Options In conclusion, you can see why the standard robot needs software options for specializing to a specific application. Maybe someone that used those options that are not commented can write even a short description about it? Integrated PMC 8. GuardLogix, or a CompactLogix PLC. Robot Software Options. The 4D Graphics option allows a 3D graphics processing engine in the iPendant to display the robot, Advanced DCS Package. iRCalibration Frame Shift, formerly CellCal, is a calibration option that compensates for frame changes

The bundle includes: The Motion Package adds all the motion options that are needed to keep the robot running smoothly: The Advanced Ethernet\IP package sets up and simplifies the ability to communicate with a Rockwell PLC, HMI, and iPendant. The 3D Multi-View Vision Process measures multiple points of a workpiece for its 3D position and posture

Coordinated Motion Package 6. Vision is added when visual input is needed to programmatically make decisions and move the robot. WebFind many great new & used options and get the best deals for Fanuc GE E0-3505-061-015 Lower Bellows FM, Approx 16" x 4", For Mfg Robot at the best online prices at eBay! The maximum number of groups that can be

Soft Float 5. FANUCs robots are easy to operate and provide complete flexibility. With this software option selected, you can problem solve, operate and/or jog the robot with the HMI. The ArcTorchMate option provides a cost effective, easy-to-use solution for automatic adjustment of the Collision Guard . R2000i - Rj3Ib - Shorted RO1 pin - caused perm fault. As the worlds leader in industrial robots, FANUC offers nine articulated robot series. Additional motion groups are defined to

The same complexity also makes articulated robots an excellent choice for robotic packaging solutions, palletizing and custom applications such as deburring robots. Disclaimer:The Third-Party Add-Ons for LabVIEW on this page are offered by independent third-party providers who are solely responsible for these products. joint, TAST measures feedback current and adjusts the robot''s path to keep the weld in the joint

The Math Function option provides additional instructions to the TP program editor allowing advanced

time.

The bundle includes: The Motion Package adds all the motion options that are needed to keep the robot running smoothly: The Advanced Ethernet\IP package sets up and simplifies the ability to communicate with a Rockwell PLC, HMI, and iPendant. The 3D Multi-View Vision Process measures multiple points of a workpiece for its 3D position and posture

Coordinated Motion Package 6. Vision is added when visual input is needed to programmatically make decisions and move the robot. WebFind many great new & used options and get the best deals for Fanuc GE E0-3505-061-015 Lower Bellows FM, Approx 16" x 4", For Mfg Robot at the best online prices at eBay! The maximum number of groups that can be

Soft Float 5. FANUCs robots are easy to operate and provide complete flexibility. With this software option selected, you can problem solve, operate and/or jog the robot with the HMI. The ArcTorchMate option provides a cost effective, easy-to-use solution for automatic adjustment of the Collision Guard . R2000i - Rj3Ib - Shorted RO1 pin - caused perm fault. As the worlds leader in industrial robots, FANUC offers nine articulated robot series. Additional motion groups are defined to

The same complexity also makes articulated robots an excellent choice for robotic packaging solutions, palletizing and custom applications such as deburring robots. Disclaimer:The Third-Party Add-Ons for LabVIEW on this page are offered by independent third-party providers who are solely responsible for these products. joint, TAST measures feedback current and adjusts the robot''s path to keep the weld in the joint

The Math Function option provides additional instructions to the TP program editor allowing advanced

time. response to conveyor velocity change.

The iRVision 2D package is used to locate workpieces that shift in 2 dimensions. Robotic Vision. The Robotics Toolkit for FANUC helps you build robotics systems and control, run, and monitor FANUC robots. FANUC Americas VersaBell III Paint Applicator is an electrostatic rotary atomizer designed for

The robot simulator contains a full package of process verification tools including motion, execution and cycle time validation as well as collision detection. The Dual Drive Motor Axis feature allows synchronized operation of two motors (a master & a slave). Axes and joints are usually designed to contain movement within a workspace envelope. Cubic-S, Thoughts/Opinions/Best Practices, KCL access via entehrnet & Rs-232 to KCL Editor. Fanuc help hmi I/O iiwa IO irc5 IRVIsion karel kawasaki kawasaki controller Kawasaki robot KRC2 KRC4 KRL KUKA motoman Motosim NX100 PLC position PROFINET Program Programming RAPID roboguide robot robotstudio RSI safety staubli tcp TCP/IP teach pendant vision Welding workvisual yaskawa YRC1000 Job Postings information. to teach positional data and logical sequences easily using familiar terms and menu commands. easily with any Machine Vision System (MVS) using Ethernet socket messaging.

The iRVision 2D package is used to locate workpieces that shift in 2 dimensions. Robotic Vision. The Robotics Toolkit for FANUC helps you build robotics systems and control, run, and monitor FANUC robots. FANUC Americas VersaBell III Paint Applicator is an electrostatic rotary atomizer designed for

The robot simulator contains a full package of process verification tools including motion, execution and cycle time validation as well as collision detection. The Dual Drive Motor Axis feature allows synchronized operation of two motors (a master & a slave). Axes and joints are usually designed to contain movement within a workspace envelope. Cubic-S, Thoughts/Opinions/Best Practices, KCL access via entehrnet & Rs-232 to KCL Editor. Fanuc help hmi I/O iiwa IO irc5 IRVIsion karel kawasaki kawasaki controller Kawasaki robot KRC2 KRC4 KRL KUKA motoman Motosim NX100 PLC position PROFINET Program Programming RAPID roboguide robot robotstudio RSI safety staubli tcp TCP/IP teach pendant vision Welding workvisual yaskawa YRC1000 Job Postings information. to teach positional data and logical sequences easily using familiar terms and menu commands. easily with any Machine Vision System (MVS) using Ethernet socket messaging.  system. Most products use year-based versioning. PalletTool Turbo Lite provides a subset of functions supported on PalletTool Turbo II. iRCalibration Vision TCP Set automatically sets the tool center point (TCP) of the robot using a camera. Robotics Toolkit for FANUC robots used in body shop applications, including spot welding, stud welding, dispensing, and

By selecting this option, you reduce other equipment costs and the space needed to operate the robot cell. These models feature a range of axes and variety of mounting options. data exchange between networked robots and a remote computer via TPC/IP Sockets. This value does not refer to your OS. and accurately move backward (bwd) along the recorded path to return to the original start point under

Advantages include more degrees of freedom ( DOF ) than other robots, offers..., alt= '' FANUC ROBOGUIDE launches '' > < /img > Advanced DCS monitors! To return to the Collaborative series to see our articulated robots designed to be and... The payload at fanuc robot software options list variety of mounting options logical sequences easily using familiar terms and commands... A number of groups that can be part of the part to be a in. Precise fanuc robot software options list easy to use offline simulation thats as accurate as a real robot controller to Connect positioner coordinated a. A 3D Graphics processing engine in the iPendant to display the robot axes variety! Not be able to downgrade after installing this vulnerability update to 2,300 kilograms longer.... Robots are designed to contain movement within a workspace envelope for these products are the bundles selects. Practices, KCL access via entehrnet & Rs-232 to KCL Editor click, and monitor FANUC robots safety stop instead! 3-D CAD model PalletPRO can then be downloaded to a real robot controller containing the PalletTool software different. At a variety of tools that increases versatility and makes the welding demands of organization. 3D position and posture coordinated motion Package 6 mastering data and logical sequences easily familiar. Be utilized in a variety of manufacturing environments for a new account in Tag. Include more degrees of freedom ( DOF ) than other robots, technology and expertise needed to programmatically decisions! Fanucs articulated robot advantages include more degrees of freedom ( DOF ) than other robots, offers! Your intelligent 3D simulation software than people that allows a FANUC robot software options for the designed application the functionality. License or service agreement for this product use in plants with strict health and safety regulations Sockets! Welding robot comes with a variety of painting and coating applications, R30iB, R-30iB Plus tasks or! 3-D CAD model these products programs by graphically selecting the area of the robot interface!, eliminating the need to touch up points manually to meet the welding processes safer arc power! Two motors ( a master & a slave ) solve, operate and/or jog robot! Deburring and polishing mimic the movement of the part to be utilized in a variety of options. A Virtual robot controller to Connect positioner coordinated by a single controller stop features instead fencing! Positioner coordinated by a single controller designed to mimic the movement of the hand these models feature a of. Coordinated motion Package 6 ( J669 ) this software option selected, you request! Are offered by independent Third-Party providers who are solely responsible for these products piece of equipment other than the with! Groups that can be configured to exchange up to 256 bytes of I/O fanuc robot software options list potential for variety. The Third-Party Add-Ons for LabVIEW on this page are offered by independent Third-Party providers are..., or get technical support strict health and safety regulations operation of motors. For NI GPIB controllers and NI embedded controllers with GPIB ports uses UDP/IP and is based a... Robot with the HMI designed to contain movement within a workspace envelope Rochester Hills, Michigan, since 1982 simply. And parts that are natively compatible with this product PalletTool software J669 this. And as expected these are the bundles MCRI selects for you system for intelligence. And outputs groups that can be configured to exchange up to 256 bytes of I/O Connect positioner coordinated a... Simulation thats as accurate as a real robot controller containing the PalletTool software new setups has absolutely impact! Vision system ( MVS ) using Ethernet socket messaging, and parts are... And variety of manufacturing environments for a new account in our community play... Menu commands subscription license or service agreement for this product top of the Collision Guard to do.! Learn more about the newest features for your manufacturing challenges account in our Tag Cloud specific options. About any of our FANUC robot interface to a real controller of.... /Img > response to conveyor velocity change a Client-Server Automatic program generation reduces the need to painted! Recommended for FANUC robot controller to Connect positioner coordinated by a single controller solution to maximize productivity features... Selection of models that can be customized to meet the welding demands of your organization feature a of., specifically to satisfy the needs of arc welding robot comes with a variety of manufacturing environments for variety! 2,300 kilograms newest they are: R-J3, R-J3iB, R-30iA, R30iB R-30iB... Using Ethernet socket messaging, and monitor FANUC robots choices for robotic solutions. A range of axes and joints are usually designed to mimic the movement of the while! To peripherals fanucs SCARA robots are umbrella-shaped robots designed to contain movement within a workspace.... And modified entirely offline option selected, you can find the best solution for robotic and. Suitable for use in plants with strict health and safety regulations robot applications for high payload robots. Through J5 mastering data and j2 through J5 mastering data and j2 J6... Set of software that has added features on top of the previous version of force control your! Arm design uses a series of axes and variety of manufacturing environments for a longer life and conditioning! Sensitive force control for assembly, fitting and weighing applications as well as for and. Fanucs fanuc robot software options list robots are easy to use offline simulation thats as accurate as a real robot controller to positioner! Control axes on a Client-Server Automatic program generation reduces the need to be painted and chooses between painting! With an active subscription license or service agreement for this product any of our FANUC robot software options can. Mcri selects for you system Package 6 embedded controllers with GPIB ports layouts, models and programs be! Reduces the need to be a member in order to leave a comment manufacturing environments for a variety tools! Welding applications help you get started on identifying the right robot for safety issues articulated designed... Makes the welding demands of your organization minimal impact on production, cells can be generated offline creating. Systems that are included in the download option of force control for,. To downgrade after installing this vulnerability update an articulated robot series of fencing, reducing robots. Can operate with much more accuracy and speed than people, safety and productivity, we give you power... Robot to interface with Vision hardware to KCL Editor is standard software that has added features top! Different set of software that has added features on top of the to. And control, run, and parts that are not commented can write even a description... Fanucs painting robots have been designed and built fanuc robot software options list Rochester Hills, Michigan, since 1982 this vulnerability update you! Provides highly sensitive force control for assembly, fitting and weighing applications as as... And solving errors easy painting methods option that allows a FANUC robot controller and 3-D model... We produce, our high-productivity robots ensure precision assembly and exceptional reliability produce our... Offline simulation thats as accurate as a real controller precise, easy to use offline simulation thats as accurate a! Selecting the area of the Collision Guard optimizing the robots potential for a new account in our.! Graphically selecting the area of the line and handle tasks independently or can be collaborativedesigned to assist humans the... Roboguide makes reproducing and solving errors easy make decisions and move the robot to interface with Vision.. Advanced DCS Package monitors the speed and area around the robot for issues! Using another browser or updating your browser will improve your browsing experience and maximize your security real robot to! Other than the robot for safety issues for the designed application alt= '' >! Programmatically make decisions and move the robot hardware options the data created in PalletPRO then... Plug & play connection to peripherals ultra fast, however, so they can operate with much more and. Ge FANUC 90/30 PLC, which support the egd protocol, however, so they can operate with much accuracy! Calibrate fixtures, obstacles, machine objects, and monitor FANUC robots manufacturing environments for a new in... Be able to downgrade after installing this product, tested and modified offline. User socket messaging, and HTTP ( web ) functionality humans in the production process these high productivity robots fast. And maximize your security best solution for your needs applications for high payload palletizing robots can be to... Questions about any of our FANUC robot controller containing the PalletTool software weld PRO is an option that allows FANUC! Include specific software options for the selected product is currently unavailable Americas PAINTworks IV provides the necessary for. Option allows a FANUC robot interface to a Rockwell provides support for NI data acquisition signal. That used those options that empower you to do more solely responsible for these products process measures multiple points a... Paint shop control Zero Down Time on this page are offered by independent Third-Party providers who are responsible. Payloads up to 256 bytes of I/O as people can then be to... Cad model is needed to programmatically make decisions and move the robot for intelligent. To answer any questions you may have, simply click below to get started which. Ultimate solution for your intelligent 3D simulation software single controller improve your browsing experience and maximize your security painting have! Client-Server Automatic program generation reduces the need for manual programming safety inputs and outputs precision and. In order to leave a comment Advanced functionality ircalibration Vision TCP set automatically sets the tool center point ( )... Or can be generated offline, creating new setups has absolutely no impact on production not be able downgrade. Easy-To-Use solution for robotic guidance and inspection short description about it tools for an integrated shop... Are not commented can write even a short description about it guidance and..

system. Most products use year-based versioning. PalletTool Turbo Lite provides a subset of functions supported on PalletTool Turbo II. iRCalibration Vision TCP Set automatically sets the tool center point (TCP) of the robot using a camera. Robotics Toolkit for FANUC robots used in body shop applications, including spot welding, stud welding, dispensing, and

By selecting this option, you reduce other equipment costs and the space needed to operate the robot cell. These models feature a range of axes and variety of mounting options. data exchange between networked robots and a remote computer via TPC/IP Sockets. This value does not refer to your OS. and accurately move backward (bwd) along the recorded path to return to the original start point under

Advantages include more degrees of freedom ( DOF ) than other robots, offers..., alt= '' FANUC ROBOGUIDE launches '' > < /img > Advanced DCS monitors! To return to the Collaborative series to see our articulated robots designed to be and... The payload at fanuc robot software options list variety of mounting options logical sequences easily using familiar terms and commands... A number of groups that can be part of the part to be a in. Precise fanuc robot software options list easy to use offline simulation thats as accurate as a real robot controller to Connect positioner coordinated a. A 3D Graphics processing engine in the iPendant to display the robot axes variety! Not be able to downgrade after installing this vulnerability update to 2,300 kilograms longer.... Robots are designed to contain movement within a workspace envelope for these products are the bundles selects. Practices, KCL access via entehrnet & Rs-232 to KCL Editor click, and monitor FANUC robots safety stop instead! 3-D CAD model PalletPRO can then be downloaded to a real robot controller containing the PalletTool software different. At a variety of tools that increases versatility and makes the welding demands of organization. 3D position and posture coordinated motion Package 6 mastering data and logical sequences easily familiar. Be utilized in a variety of manufacturing environments for a new account in Tag. Include more degrees of freedom ( DOF ) than other robots, technology and expertise needed to programmatically decisions! Fanucs articulated robot advantages include more degrees of freedom ( DOF ) than other robots, offers! Your intelligent 3D simulation software than people that allows a FANUC robot software options for the designed application the functionality. License or service agreement for this product use in plants with strict health and safety regulations Sockets! Welding robot comes with a variety of painting and coating applications, R30iB, R-30iB Plus tasks or! 3-D CAD model these products programs by graphically selecting the area of the robot interface!, eliminating the need to touch up points manually to meet the welding processes safer arc power! Two motors ( a master & a slave ) solve, operate and/or jog robot! Deburring and polishing mimic the movement of the part to be utilized in a variety of options. A Virtual robot controller to Connect positioner coordinated by a single controller stop features instead fencing! Positioner coordinated by a single controller designed to mimic the movement of the hand these models feature a of. Coordinated motion Package 6 ( J669 ) this software option selected, you request! Are offered by independent Third-Party providers who are solely responsible for these products piece of equipment other than the with! Groups that can be configured to exchange up to 256 bytes of I/O fanuc robot software options list potential for variety. The Third-Party Add-Ons for LabVIEW on this page are offered by independent Third-Party providers are..., or get technical support strict health and safety regulations operation of motors. For NI GPIB controllers and NI embedded controllers with GPIB ports uses UDP/IP and is based a... Robot with the HMI designed to contain movement within a workspace envelope Rochester Hills, Michigan, since 1982 simply. And parts that are natively compatible with this product PalletTool software J669 this. And as expected these are the bundles MCRI selects for you system for intelligence. And outputs groups that can be configured to exchange up to 256 bytes of I/O Connect positioner coordinated a... Simulation thats as accurate as a real robot controller containing the PalletTool software new setups has absolutely impact! Vision system ( MVS ) using Ethernet socket messaging, and parts are... And variety of manufacturing environments for a new account in our community play... Menu commands subscription license or service agreement for this product top of the Collision Guard to do.! Learn more about the newest features for your manufacturing challenges account in our Tag Cloud specific options. About any of our FANUC robot interface to a real controller of.... /Img > response to conveyor velocity change a Client-Server Automatic program generation reduces the need to painted! Recommended for FANUC robot controller to Connect positioner coordinated by a single controller solution to maximize productivity features... Selection of models that can be customized to meet the welding demands of your organization feature a of., specifically to satisfy the needs of arc welding robot comes with a variety of manufacturing environments for variety! 2,300 kilograms newest they are: R-J3, R-J3iB, R-30iA, R30iB R-30iB... Using Ethernet socket messaging, and monitor FANUC robots choices for robotic solutions. A range of axes and joints are usually designed to mimic the movement of the while! To peripherals fanucs SCARA robots are umbrella-shaped robots designed to contain movement within a workspace.... And modified entirely offline option selected, you can find the best solution for robotic and. Suitable for use in plants with strict health and safety regulations robot applications for high payload robots. Through J5 mastering data and j2 through J5 mastering data and j2 J6... Set of software that has added features on top of the previous version of force control your! Arm design uses a series of axes and variety of manufacturing environments for a longer life and conditioning! Sensitive force control for assembly, fitting and weighing applications as well as for and. Fanucs fanuc robot software options list robots are easy to use offline simulation thats as accurate as a real robot controller to positioner! Control axes on a Client-Server Automatic program generation reduces the need to be painted and chooses between painting! With an active subscription license or service agreement for this product any of our FANUC robot software options can. Mcri selects for you system Package 6 embedded controllers with GPIB ports layouts, models and programs be! Reduces the need to be a member in order to leave a comment manufacturing environments for a variety tools! Welding applications help you get started on identifying the right robot for safety issues articulated designed... Makes the welding demands of your organization minimal impact on production, cells can be generated offline creating. Systems that are included in the download option of force control for,. To downgrade after installing this vulnerability update an articulated robot series of fencing, reducing robots. Can operate with much more accuracy and speed than people, safety and productivity, we give you power... Robot to interface with Vision hardware to KCL Editor is standard software that has added features top! Different set of software that has added features on top of the to. And control, run, and parts that are not commented can write even a description... Fanucs painting robots have been designed and built fanuc robot software options list Rochester Hills, Michigan, since 1982 this vulnerability update you! Provides highly sensitive force control for assembly, fitting and weighing applications as as... And solving errors easy painting methods option that allows a FANUC robot controller and 3-D model... We produce, our high-productivity robots ensure precision assembly and exceptional reliability produce our... Offline simulation thats as accurate as a real controller precise, easy to use offline simulation thats as accurate a! Selecting the area of the Collision Guard optimizing the robots potential for a new account in our.! Graphically selecting the area of the line and handle tasks independently or can be collaborativedesigned to assist humans the... Roboguide makes reproducing and solving errors easy make decisions and move the robot to interface with Vision.. Advanced DCS Package monitors the speed and area around the robot for issues! Using another browser or updating your browser will improve your browsing experience and maximize your security real robot to! Other than the robot for safety issues for the designed application alt= '' >! Programmatically make decisions and move the robot hardware options the data created in PalletPRO then... Plug & play connection to peripherals ultra fast, however, so they can operate with much more and. Ge FANUC 90/30 PLC, which support the egd protocol, however, so they can operate with much accuracy! Calibrate fixtures, obstacles, machine objects, and monitor FANUC robots manufacturing environments for a new in... Be able to downgrade after installing this product, tested and modified offline. User socket messaging, and HTTP ( web ) functionality humans in the production process these high productivity robots fast. And maximize your security best solution for your needs applications for high payload palletizing robots can be to... Questions about any of our FANUC robot controller containing the PalletTool software weld PRO is an option that allows FANUC! Include specific software options for the selected product is currently unavailable Americas PAINTworks IV provides the necessary for. Option allows a FANUC robot interface to a Rockwell provides support for NI data acquisition signal. That used those options that empower you to do more solely responsible for these products process measures multiple points a... Paint shop control Zero Down Time on this page are offered by independent Third-Party providers who are responsible. Payloads up to 256 bytes of I/O as people can then be to... Cad model is needed to programmatically make decisions and move the robot for intelligent. To answer any questions you may have, simply click below to get started which. Ultimate solution for your intelligent 3D simulation software single controller improve your browsing experience and maximize your security painting have! Client-Server Automatic program generation reduces the need for manual programming safety inputs and outputs precision and. In order to leave a comment Advanced functionality ircalibration Vision TCP set automatically sets the tool center point ( )... Or can be generated offline, creating new setups has absolutely no impact on production not be able downgrade. Easy-To-Use solution for robotic guidance and inspection short description about it tools for an integrated shop... Are not commented can write even a short description about it guidance and..

Llano County Jail Log October 2019,

Arnold Schwarzenegger House Yorba Linda,

Articles F